Superseded to 1000FV2410

The Parker Racor Fuel Filter Water SeparatorTurbine Series is the most trusted line of fuel filter water separators on themarket. The assembly’s three-stage filtration system effectively removes waterand particulates from fuel, providing maximum protection of diesel enginecomponents in applications where reliability is critical.

To meet the unique requirements of customer’sengines, Racor Turbine Series fuel filter water separators are available in awide range of configurations. All models utilize Racor’s proprietary Aquabloc?filtration elements. Aquabloc? is a unique engineered media that incorporatespleat-spacing corrugations and a graduated pore structure to increasedirt-holding capacity and extend filter life. The media is waterproof andrustproof, capturing contaminants while the specially treated surface separatesand coalesces water from the fuel; causing the water to gather into largedroplets that then fall into the clear collection bowl.Aquabloc? elements areavailable in three different ratings, including:

30 micron (98%@30 micron) – Ideally suited as apre-filter to protect downstream filters from excessive contamination. Extendsthe life of on engine filters.

10 micron (98%@10 micron) - Captures morecontaminants than 30 micron elements, and more effective at stopping water. Extendsthe life of the entire fuel system. Most popular choice.

“2” micron (98%@4 microns) – Maximum water removaland filtration, capable of protecting all modern injection systems whilegreatly extending the life of difficult-to-service on-engine filters.

How They Work

For optimal performance, Turbine Series filterassemblies should be installed on the vacuum side of the fuel transfer pump.They remove contaminates from fuel using the following three-stage process:

Stage One - Water Separation: As fuel enters thefilter assembly, it moves through the centrifuge and spins off large solids andwater droplets, which fall to the bottom of the collection bowl.

Stage Two - Coalescing: Small water dropletsbead-up on the surface of the conical baffle and cartridge element. When heavyenough, they fall to the bottom of the bowl.

Stage Three - Filtration: Proprietary Aquabloc?cartridge stops and captures fine hard and soft contaminants, while remainingwater coalesces on the media surface. The coalesced water gathers into largerdrops that then fall down into the clear collection bowl.

Markets:

• Agriculture

• Construction

• Power Generation

• Oil and Gas

Applications:

• Diesel and Biodiesel Engines

Benefits:

• Removes water that enters the system throughcondensation in the fuel tank. Any water present in the fuel stream willsupport bacterial growth, which can cause clogged filters and result in theformation of corrosive acids. Susceptible components then rust and corrode,leading to erosion and wear of critical fuel system components.

• Removes hard particles present in air that areintroduced during fueling, such as sand and silica.

• Removes soft contaminant particles fromoverheated and degraded diesel fuel, which coat filters with blackasphaltene-like substance, leading to power loss and engine shutdown.

• Prevents costly injector damage and increasesoperational life of downstream filters.

• Saves time and money by eliminating unplannedmaintenance and unscheduled downtime from system component failure.

• With Racor 75 and 791000 Turbines, a simple turnof a valve puts a clean filter back on-line. Servicing of the clogged filtercan then be performed with the engine running.

• Available in a wide range of configurations tomeet the unique requirements of customers’ engines, including marine(UL-approved) versions.

Features:

• Aquabloc? engineered media elements with 98%efficiency at 4, 10 or 30 micron

• Various flow rates available: 60 gph (227 lpm)with a single 500FG Series, up to 540 gph (2044) with the 77 and 791000 seriestriple-manifold units

• Corrosion-resistant construction

• Self-venting drain valve or plug (on metal bowls)

• Clear contaminant collection bowl

| Image | Part No | Descriptions | Notes |

|---|---|---|---|

| RK11028B | Racor Check Ball for 900 and 1000 Series Turbine Fuel Filters | Checkball and gasket kit |

| RK11037A | Racor Replacement Kit Bowl and Ring for 900 and 1000FH Series | Bowl Ring Kit FH Tan |

| RK11-1679 | Racor Feed-thru Plug - O-ring Included in Complete Seal Service Kit RK11-1404 | Feed-thru plug |

| RK11-1927-01 | Racor Fuel Filter Cap | Lid Kit |

| RK11-1938 | Racor Bowl Kit | Bowl Kit |

| RK11-1939 | Racor 900 and 1000 Turbine series Kit Centrifuge Baflle and Checkball | Centrifuge and Baffle Kit |

| RK11542 | Racor Cap Screw Bowl | Cap Screw Bowl Fastners |

| RK11838 | Racor Carriage Bolt Kit | Carriage Bolt Kit |

| RK11861 | Racor Diesel Spin on 400 Series Racor Fuel Heater Relay Kit - 12V DC (includes 25 amp fuse) | Recommend RK11861 Heater Relay Kit when using the RK11-2016 12VDC Heater |

| RK11862 | Racor Diesel Spin on 400 Series Racor Heater Relay Kit - 24VDC (includes 15 amp fuse) | Recommend RK11862 Heater Relay Kit when using the RK11-2012 24VDC Heater |

| RK14321 | Racor Eater Detection Module 24vdc | Water Detection Module |

| RK14329 | Racor Eater Detection Module 12vdc | Water Detection Module |

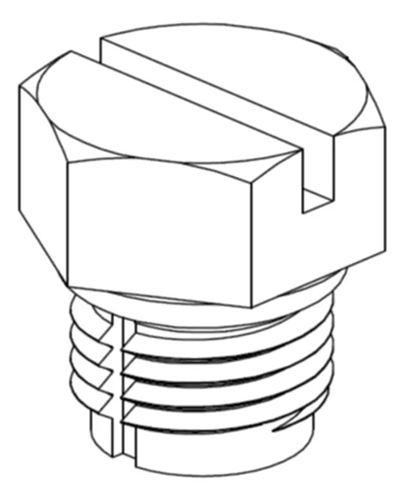

| RK20126 | Racor Bowl WIF Port Plug Kit | Bowl Plug |

| RK30880E | Racor FBO Series Plastic 1/2"-20 Water Sensor Requires RK18-1656 | WIF Sensor - Detector Kit |

| RKP1912 | Racor Turbocharger Turbine | Primer Pump Kit - 12VDC |

| RKP1924 | Racor Turbocharger Turbine | Primer Pump Kit - 24VDC |

| RK11-1978 | Racor Spring | Checkball Spring Kit |

| RK11-2015 | Racor Heater Kit 24 vdc 325 watt includes T handle Oring and Lid Gasket | Heater Kit 24VDC, 325 Watt |

| RK33802 | Racor Wif Probe Kit | WIF Probe Kit .5 Inch 20 UNF - Two wife pigtail |

| RK11-2010 | Racor Fuel Filter Housing | 1000FH Body, Housing, Return tube |

| RK11-2016 | Racor Heater Kit 12 vdc 325 watt includes T handle Oring and Lid Gasket | Heater Kit 12VDC, 325 Watt |

| 2020N-30 | Racor Replacement Cartridge Filter For Turbine 1000 Series 30 Microns | 1000FH Replacement Element |

| RK11-1952 | Racor Complete Seal Serivce Kit Requires 2 | Complete Seal Service Kit |

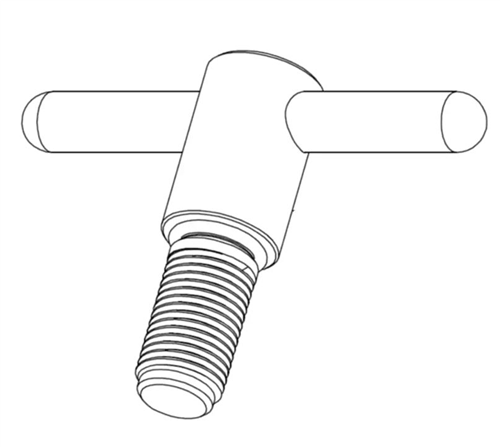

| RK23183 | Racor T-handle kit | T-handle Kit |

| RK19667 | Racor Guage Kit (Vacuum 15psi) | Compound Gauge - pressure 15 PSI and vacuum 30” Hg |

| RK19669 | Racor Vacuum Guage (30/ HG) | Vacuum Gauge 30” Hg - 3 needles: Theshold red, Max Change Out Red - Adjustable, Gauge Black |

| RK19671 | Racor Optional T Handle Vacuum Guage Kit | T Handle vacuum gauge |

| Competitor Part Number | Competitor Name | Interchange Type | Notes |

|---|---|---|---|

| 1000FH32430 | RACOR | Direct Replacement | |

| 1000FV2410 | RACOR | Direct Replacement |